In July 2020, Nikon Corporation issued a recall for its Nikon F6 film camera after finding that units sold on or after July 22, 2019, contained dibutyl phthalate (DBP), which is an endocrine disruptor prohibited by the European Union (EU) Restriction of Hazardous Substances (RoHS) Directive.

In production since 2004, the once best-selling camera has become more of a niche product in recent years, and the recall affects a little over 150 cameras that had been sold past the date that the DBP restriction came into effect. The case represents one of the few times a household name has been publicly announced as running afoul of RoHS compliance, but that is not to suggest that RoHS enforcement is a rarity.

The Quiet Enforcement of the RoHS Directive

The goal of the RoHS Directive is to protect both the environment and human health by restricting the use of certain substances identified as dangerous either to human health or the environment. The efficacy of the directive isn’t measured by how many violators are penalized, but by how many toxic substances are prevented from entering the marketplace. In a report requested by the European Commission, the directive was shown to be responsible for large decreases in the use of the listed substances.

This has been achieved through measured enforcement by relevant authorities in EU member states and self-reporting conducted by companies whose products and equipment fall within the directive’s very broad scope

Learn more about the true cost of RoHS compliance in our whitepaper, Understanding EU RoHS Exemptions to Minimize Costs and Risk

Self-Reporting

The penalties associated with the RoHS Directive vary depending on a number of factors, including how the breach was discovered and the severity. The voluntary disclosure of non-compliance often results in a collaborative approach to remediation. This method resolves the infraction while frequently keeping a company’s brand out of the news. For example, a well-known electronics manufacturer reported a minor breach of the requirements when it discovered that a subcomponent had a coating with more than the allowed amount of a listed substance. The company informed the relevant authority, and agreed upon a multiphase, time-limited plan to remove that component with one that was compliant.

As the Nikon case demonstrates, not all self-reporting stays out of the public eye. Early indications show Nikon identified their breach and responded appropriately, however, it still resulted in a product recall. The amount of a restricted substance as well as its location within a product and the likelihood of exposure will be considered when determining the next steps.

It should be stressed here that other Nikon cameras have fully met compliance standards and there is no cause for concern when using them as intended.

Enforcement Authorities

The EU RoHS Directive is actively enforced by the member states, which coordinate their efforts through regular meetings of formal Administrative Cooperation Groups (AdCos). The relevant enforcement authority for a specific product is typically determined by a product’s point of entry into the EU, but can also be decided by where the company is headquartered. The AdCos share information related to targeted industries or products, audit results, and enhance the ability of authorities to discover breaches and hold companies to account.

The directive is enforced on a national level, however, member states will harmonize enforcement throughout the EU from July 2022. National authority bodies will need to submit national enforcement plans, including audits and investigations based on risk level and the execution of laboratory tests to determine if products meet the safety standards of the EU RoHS Directive and a wide range of other legislation.

What Happens When Substances Are Found

Each member states’ enforcement authority will have slightly different processes after finding a restricted substance in a product, however, the following steps serve as a general guide.

Notice

The body will notify companies that their product has been found in violation of the RoHS Directive and next steps will be outlined in this notice. Enforcement authorities will request technical documentation at this time and establish a timeline for delivery.

Enforcement authorities typically request the following data in these documents:

- Contact information for the individual responsible for compliance.

- Company information such as size, sales, and product catalog.

- General overview of processes that assist in RoHS compliance efforts.

- Overview of data quality systems, when a company relies on supplier submission to demonstrate compliance.

Physical Inspections

Enforcement authorities find non-compliant products by spot-checking goods in the market. They will purchase a product from a store and take it to a lab to identify the substances present. This triggers the process, however, further physical testing may be ordered to gauge the exact severity of a breach.

Removal From Market

Non-compliant products are not allowed on the market and removing these products from shelves is one of the top priorities of companies and authorities. Voluntary recalls may be ordered, such as in Nikon’s case, or forced removal as issued by a member state authority. Most companies collaborate closely with the enforcement authorities and choose to handle removals internally, as public exposure can have lasting financial and reputational repercussions.

Possible Penalties

Fines vary depending on where the infraction occurred. In addition to set fines, companies may be ordered to pay for the testing administered by the state. The true cost of RoHS non-compliance, however, lies in the loss of market access. A report estimates the cost of an electronics product recall at $11.71 million USD. When Sony Corporation had to recall millions of units of their flagship product, the Playstation 2, in 2001 due to an exceedance of the permitted levels of cadmium, the company lost out on an estimated $150 million USD worth of Christmas season sales.

How to Mitigate Risks

Substance tracing is essential to stopping RoHS breaches before they happen. Companies with a transparent supply chain are better equipped to identify substances of concern in their products and take action (including component testing when appropriate) before those products hit the market.

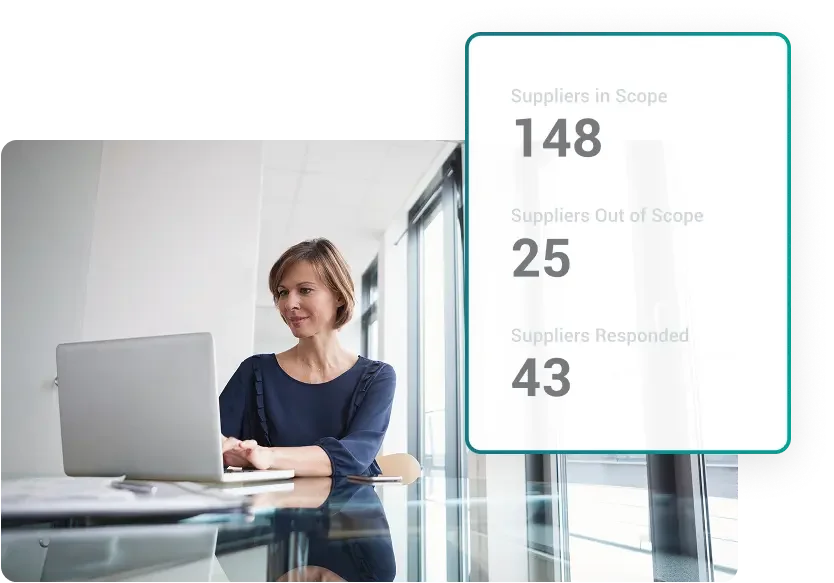

Assent enables companies to undertake robust RoHS compliance measures, including automated data collection and validation and centralized reporting to identify risks quicker.