The automotive industry has a reputation for being a leader in sustainable manufacturing, including the invention of hybrid and electric vehicles (EVs) that reduce global reliance on fossil fuels and carbon emissions. Manufacturers often compete to improve fuel efficiency and tout how green their vehicles are. Because vehicles have a large impact on consumers’ personal carbon footprint, environmental performance has become a powerful motivation in customer purchasing decisions.

However, propelled by investor expectations and mounting regulatory pressures, the sustainability landscape has shifted gears in the past few years to incorporate a broader range of factors. Today, environmental, social, and governance (ESG) is considered the gold standard in corporate sustainability, with a balanced focus on all three pillars. While environmental indicators still play a large role in how automotive manufacturers measure sustainability, focusing only on green performance gives a shallow view of corporate sustainability. Deep sustainability isn’t just measured in carbon footprints, energy efficiency, or what happens to the materials at the end of the product’s life cycle — according to investors and regulators, it includes the full scope of ESG topics, including human rights, diversity, and bribery and corruption.

Sustainability reporting is expected to dig deeper into the full life cycle of a product, not just post-production. For example, on the road, EVs can check many boxes under the environmental category, but there are equally important pre-production considerations under social and governance impacts. The production of lithium-ion batteries has a significant environmental and social footprint that is only captured when you look at the supply chain. Depending on how they are manufactured and where their components are sourced, batteries can be green, but they may present significant human rights risks. If you aren’t looking at the total picture, you’re missing the risks that can do the most damage to your brand.

Let’s take a closer look at why sustainability has to go deeper than just being green, especially if you’re an automotive manufacturer with a significant and complex pre-assembly supply chain.

Get the facts about automotive manufacturing product compliance, supply chain sustainability management, and responsible minerals sourcing. Download Assent’s Navigating the Compliance Landscape: Automotive eBook.

Sustainability Is a Supply Chain Issue

ESG requirements challenge automotive manufacturers to look at the deeper picture, so that being low emission to ensure low emissions aren’ the only thing sustainable about their vehicle. The impact of your vehicles isn’t just what comes out of your products post-production (e.g, emissions and waste), but also what goes into them pre-production. Namely, ESG management includes tracking where materials come from as well as who is responsible for their processing. It’s about more than environmental footprint — it’s your total impact on the people within your supply chain. The data points about your total impact are all contained within the supply chain and require supply chain transparency to accurately understand and report.

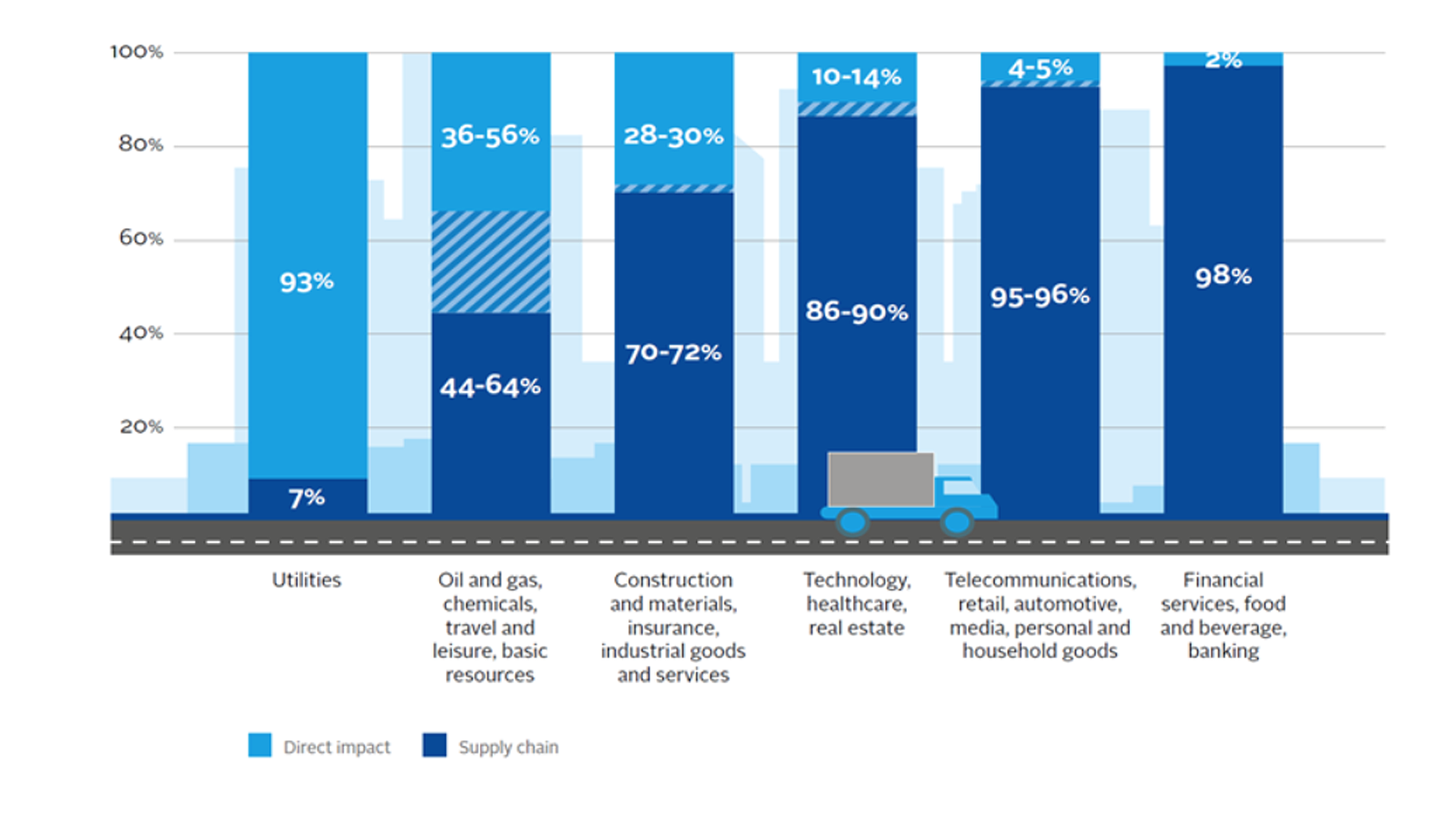

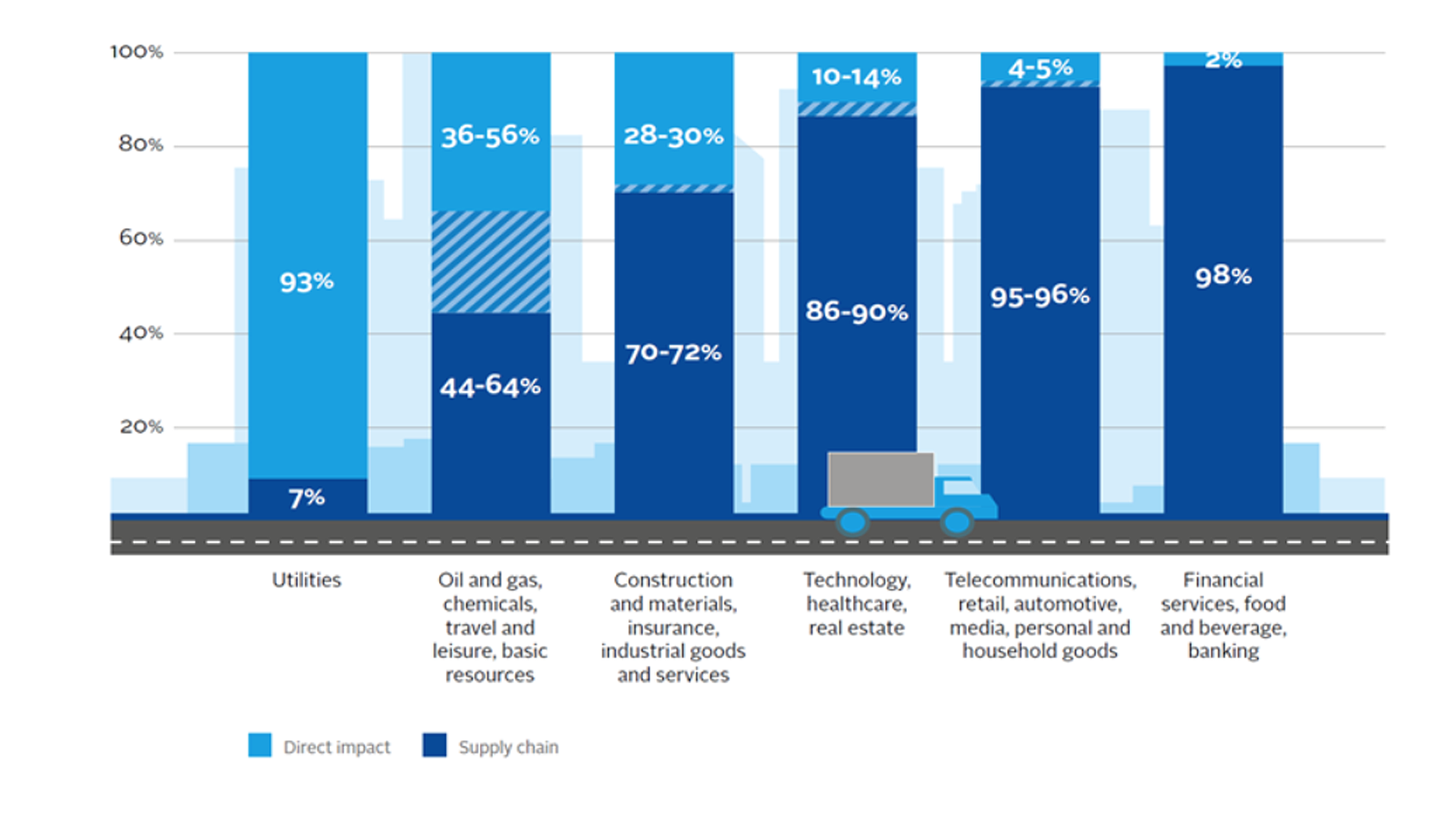

The majority of an automotive manufacturers’ ESG impacts are hidden within their supply chain — approximately 95 percent, according to a 2017 study conducted by the UN Principles for Responsible Investment.

Image credit: UN Principles for Responsible Investment. (2017). Managing ESG Risk in The Supply Chains of Private Companies and Assets. https://www.unpri.org/download?ac=1894.

In the case of EV batteries, most of these risks are related to cobalt sourcing. Cobalt is an essential mineral in EV batteries, and the automotive industry is facing mounting scrutiny over its use because the majority of it is mined in the Democratic Republic of the Congo (DRC). The Responsible Minerals Initiative (RMI) has identified the DRC as a country of high risk for:

- Forced and compulsory labor

- Corruption and bribery

- Human rights abuses

Even though cobalt is not listed as a conflict mineral, and there is currently no mandatory cobalt reporting requirement for automotive manufacturers, these risks can pose a much larger threat to your brand and market access than environmental ones. When EVs and hybrids first entered the market, their environmental performance gave them a competitive edge, but today’s consumers and investors are increasingly conscious of the deeper supply chain risks associated with the minerals in their batteries. For automotive manufacturers, it’s no longer enough to be green because public awareness has evolved to think a step deeper, incorporating concerns around the materials that power their low-emission vehicles.

How to See Deeper Into Your EV Supply Chain

In order to manage the human rights and responsible minerals risk in your supply chain and prevent brand damage and market access loss, you need the ability to see deeper into your supply chain. This means that there should be a flow of data that includes the source of your cobalt and who handles it before it reaches you.

This is no small task, but there are tools you can use to capture this data. The automotive manufacturing industry is moving toward due diligence for a broader set of responsible minerals, beyond tin, tungsten, tantalum, and gold (3TGs). For example, the RMI released the Extended Minerals Reporting Template (EMRT) to standardize supply chain reporting for cobalt and mica. Manufacturers with batteries in their durable goods are beginning to track the origin of cobalt and validate chain of custody, which is vital as we move toward electrification and reduce greenhouse gas emissions.

However, there are limits to what the surveys can uncover since they rely on your suppliers providing accurate information. As a result, data collection standards work best when used in tandem with a system that streamlines supplier outreach, validates data, and rolls it up into actionable disclosures. Furthermore, the risk assessment included in the OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas suggests that manufacturers work to gain insights into the behaviors of upstream actors however possible. One method of gaining these insights is to screen supplier legal affiliations and beneficial ownership against media and watch lists.

It’s also important to be able to visualize all the data you collect from your cobalt supply chain and score the degree of risk each link presents to your organization. Applying a scoring logic helps manufacturers rank risks and address them in priority order. Scoring also lets you chart the maturity of your supply chain sustainability program to track results and reduce risk over time. Once you’ve gathered your information, it’s important that it tells a story. Through visualization, including scoring and risk assessments, you’re able to understand the maturity level of your supply chain actors and support the development of action plans to move your sustainability program forward.

Building Credible Sustainability

Investors and the general consumer public not only expect deeper transparency into a manufacturer’s supply chain — sustainability claims also need to be validated by credible data or third parties. For example, manufacturers the world over have codes of conduct, but those codes of conduct are created in-house and don’t tell institutional investors anything meaningful about a product’s sustainability impact. Manufacturers that specifically align their efforts with an internationally-recognized sustainability framework, like the Global Reporting Initiative (GRI), are able to prove their due diligence to any investor or auditor worldwide.

Learn how the Assent Supply Chain Sustainability Platform will optimize your EMRT data collection, reporting, and ESG management: Get your copy of the Assent Solution Guide today.