What is the EU Conflict Minerals Regulation?

Back in 2017, the European Commission introduced a new regulation to help prevent the funding of armed conflict in mineral supply chains. This rule, the EU Conflict Minerals Regulation, officially took effect in January 2021 and applies to EU importers of tin, tungsten, tantalum, and gold — commonly known as the 3TGs.

Under the regulation, importers must carry out supply chain due diligence. That means they need to make sure their sourcing practices don’t support conflict or instability in places like the Democratic Republic of the Congo (DRC) and other conflict-affected or high-risk areas (CAHRAs).

Even if they are not legally required to comply, many manufacturers have voluntarily aligned with the EU Conflict Minerals Regulation in order to meet customer demands for the EU market. In many cases, it’s a natural extension of the work they’re already doing to meet the U.S. Dodd-Frank Act (specifically Section 1502) and other responsible minerals sourcing initiatives.

What is the EU Conflict Minerals Regulation? The information and resources in this article will explain everything you need to know.

These minerals can be found in products in nearly every sector, including the automotive, apparel, electronics, construction, medical, and aerospace industries.

While they are the primary focus of conflict minerals regulations, industry groups are expanding their efforts to include other high-risk materials like cobalt, especially given its significant presence in the DRC.

What are conflict minerals? Check out our article to learn more and how to tell if they’re in your supply chain.

EU Conflict Minerals Regulation Snapshot

Here are some fast facts about the EU Conflict Minerals Regulation and its impact on manufacturers:

- Approximately 600 to 1,000 EU importers are directly affected

- Approximately 500 3TG smelters and refiners globally are impacted

- Thousands of companies around the globe that sell products into the EU have seen market pressure to voluntarily report as a part of their overall corporate responsibility strategies

- Threshold standards for 3TGs and ores cover at least 95% of all EU imports

- EU member states are responsible for enforcement of the rule in their own jurisdictions

When Did the European Conflict Minerals Law Pass?

In its resolutions of October 7, 2010; March 8, 2011; July 5, 2011; and February 26, 2014, the European Parliament called for the EU to legislate along the lines of the U.S. law on conflict minerals, Section 1502 of the Dodd-Frank Act.

Why Is EU Conflict Minerals Reporting Necessary?

The EU Conflict Minerals Regulation was created to ensure that minerals in EU products weren’t coming from conflict zones or as a result of illegal exploitation, such as child labor.

Although conflict minerals are important for industrial development, their supply chains can hide risks if you don’t know which mines and smelters they’re being sourced from.

That’s why the regulation requires manufacturers to conduct supply chain due diligence and engage in responsible mineral sourcing.

Assent’s experts visited the DRC to see firsthand how cobalt and other conflict minerals are mined. Get a recap of their journey:

You can watch all three parts of our documentary miniseries here.

A responsible sourcing program lets your business contribute to the peace, economic health, and human rights in the regions where these minerals are sourced.

How to Achieve Conflict Mineral Compliance in the EU

The regulation states that due diligence must be in line with the Organisation for Economic Co-Operation and Development (OECD)’s Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas. The steps laid out in the guidance are intended to help companies identify, mitigate, and prevent the risks associated with the extraction, handling, manufacturing, and sale of conflict minerals throughout their operations.

For more expert tips and insights, read our article: Conflict Minerals Compliance Basics: What to Know for 2025.

The guidance requires EU importers of 3TGs to:

- Establish strong company management systems to support supply chain due diligence

- Identify and assess risk in the supply chain through comprehensive surveying

- Design and implement a strategy to respond to the risks identified

- Carry out an independent third-party audit of supply chain due diligence at various points in the supply chain

- Report on efforts made toward supply chain due diligence policies and practices as an integral part of their wider sustainability programs

Need help? Assent’s responsible sourcing software can help you meet your compliance requirements. See it in action by booking a demo now.

Who Is an Importer Under the Conflict Minerals EU Regulation?

The rule deems EU importers to be:

- Any natural or legal person declaring the release of minerals or metals for free circulation within the meaning of Article 201 of EU Regulation 952/2013

- Any person on whose behalf such a declaration is made

Let’s simplify that. In the context of the EU Conflict Minerals Regulation, an importer refers to any individual or company (what the EU calls a “natural or legal person”) that brings a 3TG into the EU and officially declares those materials to enter the EU market.

More specifically, it means someone who files the paperwork to have these minerals or metals released for “free circulation” — a customs term defined in Article 201 of EU Regulation 952/2013. Free circulation means the goods have cleared EU customs and can move and be sold throughout the EU just like any locally produced goods.

So if your company is responsible for submitting those customs declarations, it’s considered the importer and is legally responsible for meeting the due diligence requirements under the EU Conflict Minerals Regulation.

Conflict Minerals Compliance Software: The Assent Advantage

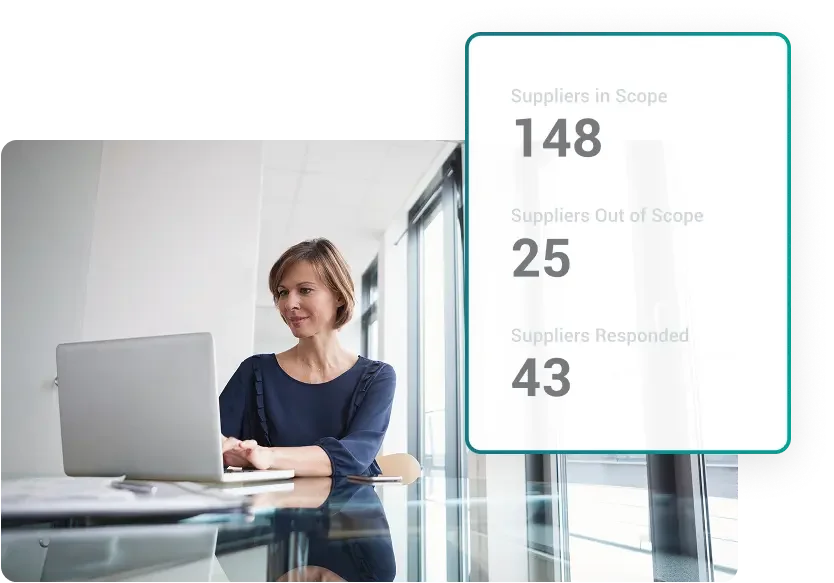

The Assent Sustainability Platform allows complex manufacturers to survey suppliers using an industry-standard format, and assess supplier declarations for overall risk, smelter risk, and status. By combining the platform with comprehensive managed services, Assent’s clients receive guidance, expertise, and hands-on support with their conflict minerals programs.

Learn more about Assent’s conflict minerals software here to see how we can help you detect and prevent risks in your responsible sourcing program.

FAQ: EU Conflict Minerals

Get expert answers to the common questions about responsible mineral sourcing.