Update: On November 10, 2025, the U.S. Environmental Protection Agency (EPA) proposed amendments to the Toxic Substances Control Act (TSCA) Section 8(a)(7) rule that make this article out of date. To learn more about the amendment to article reporting, read our recent article here.

“Articles are manufactured goods or finished products — and the chemicals in them are subject to [the Toxic Substances Control Act (TSCA)].” So says Michal Freedhoff, the Environmental Protection Agency (EPA) Chemicals Chief. She made the statement during prepared remarks to the Product Stewardship Society as a keynote speaker for their annual meeting in September. It signals what experts, including myself, have been saying for months: the EPA is moving toward greater regulation of finished products under TSCA.

It’s important to note that this isn’t a change in legislation, only in its application. In her statement, Freedhoff noted the legal text of TSCA defines chemical “manufacture” as the importation of an article containing a chemical, as well as creating a chemical from its components. She should know — she helped write the law.

This latest move is akin to the 2015 Court of Justice of the European Union (CJEU) ruling that interpreted the definition of “article” within the Registration, Evaluation, Authorisation, and Restriction of Chemicals (REACH) Regulation. The resulting “once an article, always an article” ruling required many companies to overhaul their compliance programs.

What TSCA Article Restrictions Mean for Companies

The TSCA list of substances contains thousands of chemicals, but for article manufacturers and importers in the U.S., the key substances of interest are those restricted under TSCA Section 6. On January 6, 2021, the EPA announced new rules for five persistent, bioaccumulative, and toxic (PBT) substances. From March 8, 2021, companies with the following substances in their supply chains face new obligations:

- Decabromodiphenyl ether (DecaBDE), CAS 1163-19-5

- 2,4,6-Tri-tert-butylphenol (2,4,6 TTBP), CAS 732-26-3

- Hexachlorobutadiene (HCBD), CAS 87-68-3

- Pentachlorothiophenol (PCTP), CAS 133-49-3

The fifth chemical, phenol, isopropylated, phosphate (3:1) (PIP 3:1), CAS 68937-41-7, received a special no action assurance (NAA) order after industry warned of wide-scale supply disruptions. Companies using PIP 3:1 in their finished articles must be ready to meet new requirements by October 31, 2024. Due to the amount of work required to identify impacted parts, companies should consider proactively starting the process of phasing out PIP 3:1 months ahead of this deadline, if not more.

To comply with the new PBT rules, companies must:

- Document the use of restricted substances in parts, materials, and products.

- Communicate the presence of any TSCA-restricted substances contained in a product to downstream customers.

- Retain documentation for a minimum of three years.

The EPA will be taking another look at their PBT rules in early 2023, but warned companies it’s more likely to strengthen them than walk them back.

A Stronger TSCA

This is part of the continuing trend of leveraging TSCA to achieve results similar to the REACH Regulation. In 2016, TSCA was recast under the Lautenberg Chemical Safety Act to strengthen the regulation’s ability to safeguard human health and the environment from toxic chemical exposure. The law mandated enhanced chemical risk evaluations with clear and enforceable deadlines, increased public transparency, and allocated more funds for the EPA to carry out its work.

While TSCA is still different from the REACH Regulation, looking to the EU’s dominant product compliance standard can provide a roadmap for companies building a TSCA compliance program.

Scoping TSCA Restrictions

Where REACH has its Candidate List of substances of very high concern (SVHCs), TSCA has its Section 6 restrictions — expected to increase by 10 new substances within the next year. Companies must engage their supply chains to identify if their products contain these listed substances. The latest TSCA restrictions are, by and large, not part of existing declarable substance lists, reducing the likelihood of quick identification from your compliance programs.

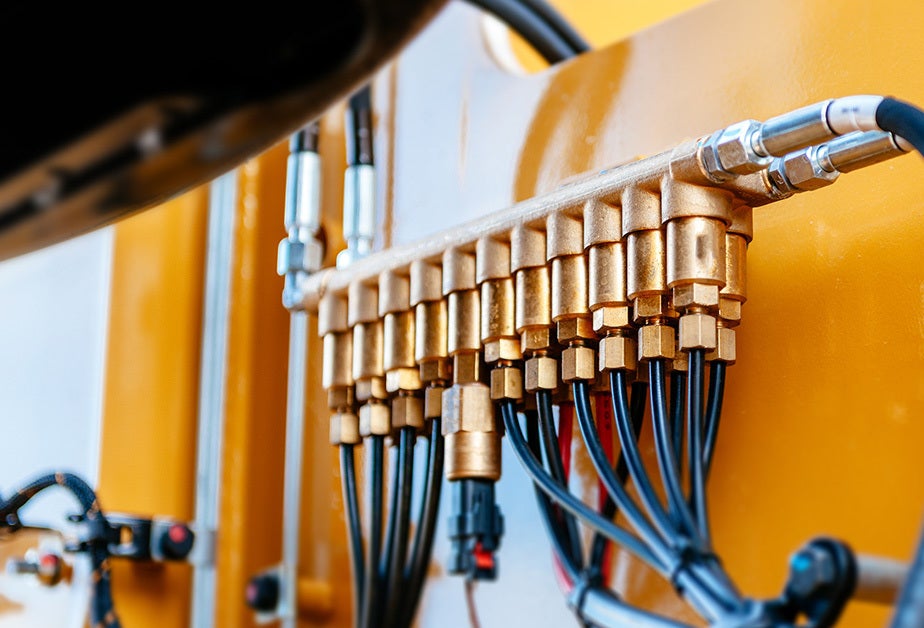

Scoping supply chains for PBTs, and many of the chemicals slated for future rules, can pose a challenge to manufacturers and importers, as these chemicals enter the supply chain early and are typically found in subcomponents, such as wire sheaths. To correctly assess the risk your company faces, you’ll need a deep dive into your supply chain to collect data from the suppliers to your suppliers. This can be a time-consuming process, which is why the EPA and industry experts advise companies to start scoping immediately.

Enforcement Bodies Not Backing Down

Decades ago, lobbying was an effective means of reducing regulatory burden to companies, but times have changed. In 2020, a multi-industry push for the postponement of the Substances of Concern In articles, as such or in complex objects (Products) (SCIP) database was refused by the European Commission. Hundreds of companies scrambled to meet their deadline and avoid non-compliance penalties. The deadline for the EU Medical Device Regulation (MDR) was delayed by a year, but that also happened in the context of a pandemic. Many medical device companies had argued for a longer grace period and were denied.

The EPA has been firm in their signals to companies. Start preparing now, through an article-centric lens, or risk incurring non-compliance penalties.

How Assent Helps

As the leader in supply chain sustainability management, our goal is to help you see deep into your supply chain to identify who and where you source products from, empowering you to make data-driven business decisions. Our unique platform combined with our diverse Regulatory team will help you manage risk, accelerate market access and growth, protect your brand’s reputation, and build a sustainable business.

Learn more by contacting our experts.