Wouldn’t it be convenient if every product you bought from your supply chain came with a full ingredient list? Then you could know exactly what’s in it, making product compliance straightforward and simple.

Unfortunately that information seldom exists, and if it does, it’s likely to be outdated quickly. If you’ve been told that the stack of Safety Data Sheets (SDS) on your desk and a legacy Full Material Disclosure (FMD) database is enough to “cover compliance”, you’re being sold a partial shortcut, not a complete solution.

Both SDSs and FMDs have their place in materials compliance. But relying on them alone leaves manufacturers exposed to costly blind spots, potential rework, and regulatory penalties. That’s because Safety Data Sheets and Full Material Disclosures were simply not designed to guarantee market access, mitigate enforcement risk, or scale supplier collaboration.

A hybrid approach to material compliance management is what you need to support proactive product compliance. Here’s why:

SDS Compliance ≠ Product Compliance

The purpose of SDS doesn’t align with materials compliance, especially for articles. So why are Safety Data Sheets important? Their purpose is hazard communication for substances. They inform safe handling, storage, and disposal of chemicals but don’t generally demonstrate product conformity for regulations like RoHS, REACH, or TSCA.

SDSs are generally aligned with the UN Globally Harmonized System (GHS), and because each country enacts their own GHS requirements, the details contained in an SDS will vary, including any regulations that may be referenced in Section 15.

In the U.S., GHS requirements are enshrined in the OSHA Hazard Communication Standard. In the EU, it’s generally managed through the Classification, Labeling and Packaging (CLP) regulation.

Some of the challenges with using SDSs to meet material compliance requirements include:

- Scope limitations: Not every material or product requires a Safety Data Sheet. SDS apply mostly to chemicals and mixtures, not finished articles — where most market-access risk lies.

- Incomplete data: Proprietary details are often withheld, leaving gaps. Not all substances are required to be listed on an SDS page, so they seldom provide reliable “full ingredient lists”, especially for substances considered a trade secret.

- Static documents: They age quickly any time suppliers or materials change.

- Manual review: Most SDS sheets will require manual review to find the information you need, as well as manually compiling data from multiple SDSs to assess a finished product from a bill of materials (BOM).

The result? Missing SDS for most of your purchased components, outdated and incomplete composition information for the ones you do have, and outdated information with few regulatory references. You will experience blind spots and repetitive rework every compliance cycle as regulations add more substance restrictions or new regulations emerge.

Full Material Disclosures Can Go Stale Fast

At first glance, an FMD looks comprehensive. But it’s often incomplete and, without frequent updates, it quickly becomes outdated. This creates compliance risks instead of resolving them.

Key limitations of FMDs include:

- Proprietary holdback: Many suppliers will not provide a “full” FMD disclosure. They may insist on a “holdback” of information they consider proprietary (often, manufacturers we work with find that up to 10% is commonly held back). Unfortunately, this often includes substances like per- and polyfluoroalkyl substances (PFAS), flame retardants, and phthalates, which are increasingly regulated.

- Data decay: Like SDSs, supplier FMD data is a snapshot in time. It’s not a declaration against a regulation that needs to be kept current for legal purposes. It’s a recipe that’s being used that day. Legacy databases of FMD collected in the past may not reflect material changes that do not affect form, fit, or function.

- Coverage gaps: Many suppliers — especially outside electronics — struggle to provide FMDs. Some industries are better at providing FMDs than others, based on the norms of that sector. With little regulatory pressure to provide a “full ingredient list”, many suppliers are not willing to put in the time, effort, or business risk of providing this level of information.

- Supplier fatigue: An “FMD-first or bust” strategy creates resistance and slows progress. If suppliers provide an FMD with a proprietary hold-back, it creates a double-ask — first for the FMD and then a follow-up for an “absence declaration” against anything being held as proprietary.

Stale or incomplete FMDs can leave teams scrambling during audits or when responding to customer data requests.

A Better Path to Reduce Risk & Ensure Compliance

While some compliance management vendors market SDS or FMD collection as “good enough,” these shortcuts leave huge data gaps and often create bigger problems down the road. The real question isn’t whether SDSs or FMDs have value. It’s this: If your current compliance management software prioritizes these data sources, can it really keep you compliant year after year?

Assent helps manufacturers move beyond the limits of SDS and FMD-only strategies by delivering a compliance approach that is flexible and defensible:

- Collect what works, when it works: Support FMDs where practical; supplement with targeted regulatory declarations (RoHS, REACH, PFAS) where needed for full coverage.

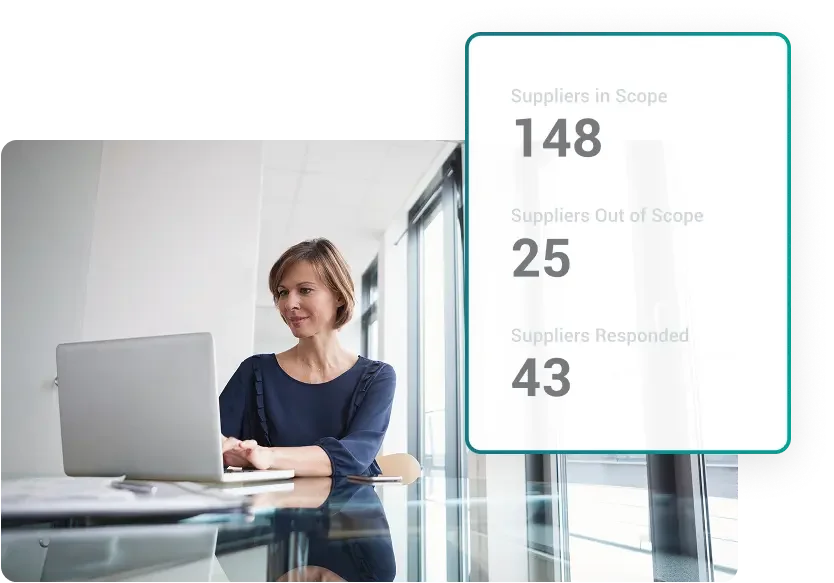

- Supplier engagement at scale: Drive outreach, education, and escalation across languages and time zones to lift supplier response rates.

- Automation + carry-forward: Each cycle builds on the last, reducing fatigue and shortening timelines year over year. Assent’s platform additionally matches part-level data against your Bill of Materials to provide a full product assessment and documentation for customers and technical files.

- Scalable platform: Expand beyond simply focusing on product compliance into product sustainability, and even manage your suppliers for responsible sourcing regulations, without layering on new tools.

Buyers who choose Assent consistently see stronger ROI because of our holistic approach to compliance, including supplier engagement, validation, and automation are built in from the start. This leadership was validated in the 2025 Verdantix Product Compliance Green Quadrant, where Assent earned the highest scores in supplier data management and compliance assurance, product compliance analytics and reporting, and brand preference. We have also seen that Assent customers are able to identify more supply chain PFAS with our methodology versus those who rely on previously-collected FMDs.

With Assent’s product compliance software, your compliance team can more quickly and readily qualify products. You’ll spend less time chasing data and more time protecting revenue, preserving market access, and reducing risk.

Speak to an Assent expert today and learn how you can close the compliance gap.

FAQ: Safety Data Sheets & Full Material Disclosures for Compliance Management

Many manufacturers wonder how Safety Data Sheets and Full Material Disclosures fit into product compliance management. Get answers to common questions from our experts.