What You Need to Know Right Now

The European Commission has formally adopted delegated directives to revoke and renew key Restriction of Hazardous Substances (RoHS) exemptions for the use of lead in the following applications (from exemption pack 22):

- Lead as an alloying element in steel, aluminum, and copper: 6(a), 6(a)-I, 6(a)-II, 6(b), 6(b)-I, 6(b)-II, 6(b)-III, 6(c)

- Lead in high-melting temperature solder: 7(a), 7(a)-I to 7(a)-VII

- Lead in glass or ceramic components: 7(c)-I, 7(c)-II, 7(c)-V, 7(c)-VI

Any company that places electrical and electronic products or parts on the European Economic Area (EEA) market, or sells them to companies that sell into the EEA, should immediately assess whether lead is in any parts they use, whether they use any of the affected exemptions, and whether they will need to continue using those exemptions in the future. Time is extremely limited to apply for the renewal of necessary exemptions, or to identify and source lead-free parts.

These RoHS exemption updates will have a widespread impact on global manufacturing supply chains, and the regulatory timeline is significantly shorter than expected.

Looking for more information on RoHS compliance? Download Assent’s RoHS Handbook: Your Guide to Compliance.

Confirmed RoHS Exemption Expirations & Revocations

Exemptions that will be revoked, with a phase-out period of 12–18 months:

- 6(a): Lead as an alloying element in steel for machining purposes and in galvanized steel containing up to 0.35% lead by weight

- 6(b): Lead as an alloying element in aluminum containing up to 0.4% lead by weight

- 6(b)-I: For equipment categories 1–7 and 10

- 6(b)-II: For equipment categories 1-7 and 10

Exemptions that will expire on June 30, 2027:

-

- 6(a)-I: Lead as an alloying element in steel for machining purposes containing up to 0.35% lead by weight (reworded)

- 6(a)-II: Lead as an alloying element in batch hot-dip galvanized steel components containing up to 0.2% lead by weight (new exemption)

- 6(b)-I: Lead as an alloying element in aluminum containing up to 0.4% lead by weight, provided it stems from lead-bearing aluminum scrap recycling (for equipment categories 9 IMCI and 11 only)

- 6(b)-II: Lead as an alloying element in aluminum for machining purposes with a lead content up to 0.4% by weight (for equipment categories 9 IMCI and 11 only)

- 6(b)-III: Lead as an alloying element in aluminum casting alloys containing up to 0.3% lead by weight, provided it stems from lead-bearing aluminum scrap recycling (new exemption)

- 6(c): Copper alloy containing up to 4% lead by weight

- 7(a): Lead in high melting temperature type solders (i.e., lead-based alloys containing 85% by weight or more lead)

- 7(c)-I: Electrical and electronic components containing lead in a glass or ceramic other than dielectric ceramic in capacitors (e.g., piezoelectronic devices, or in a glass or ceramic matrix compound)

Exemptions that will expire on December 31, 2027:

- 7(a)-I to 7(a)-VII: Very specific applications of lead in high melting temperature type solders (i.e., lead-based alloys containing 85% by weight or more lead, for forming stable electrical connections) (new exemptions)

- 7(c)-II: Lead in dielectric ceramic in capacitors for a rated voltage of 125 V AC or 250 V DC or higher

- 7(c)-V: Electrical and electronic components containing lead in a glass or glass matrix compound that fulfills five very specific functions (new exemption)

- 7(c)-VI: Electrical and electronic components containing lead in a ceramic that fulfills any of the following functions:

- 1) For use in piezoelectric lead zirconium titanate (PZT) ceramics

- 2) For providing ceramics with a positive temperature coefficient (PTC) (new exemption)

Your RoHS Compliance Action Plan

Urgent action is required if you are affected by any of the above changes.

- Identify which of the above-listed exemptions are used by your organization and within your supply chain.

- Evaluate internally if you still need an exemption by identifying whether there are feasible, lead-free alternative parts available. You will need to engage your suppliers and gain transparency into which substances are in their parts.

- If exemptions are still required, we recommend contacting your trade association and joining any working groups that can coordinate the application for the renewal of the exemption(s). Keep in mind that applications for the exemptions expiring on June 30, 2027, need to be submitted to the European Commission by December 31, 2025 (18 months before), less than six months away. Assent’s regulatory experts Steve Andrews and Sue Fortunato-Esbach are the vice-chairs of the Umbrella Project, a grouping of trade associations that work together to apply for the renewal of exemptions. The Umbrella Project will submit the renewal applications for the following exemptions to the European Commission by December 31, 2025: 6(a)-I, 6(a)-II, 6(c), 7(a), 7(c)-I

This process should be taken seriously. If you rely on an affected exemption, and it expires because a renewal was not applied for, or the renewal application was not robust enough, you will no longer be able to sell any products containing lead in that application into the EEA.

RoHS Exemption Management With Assent

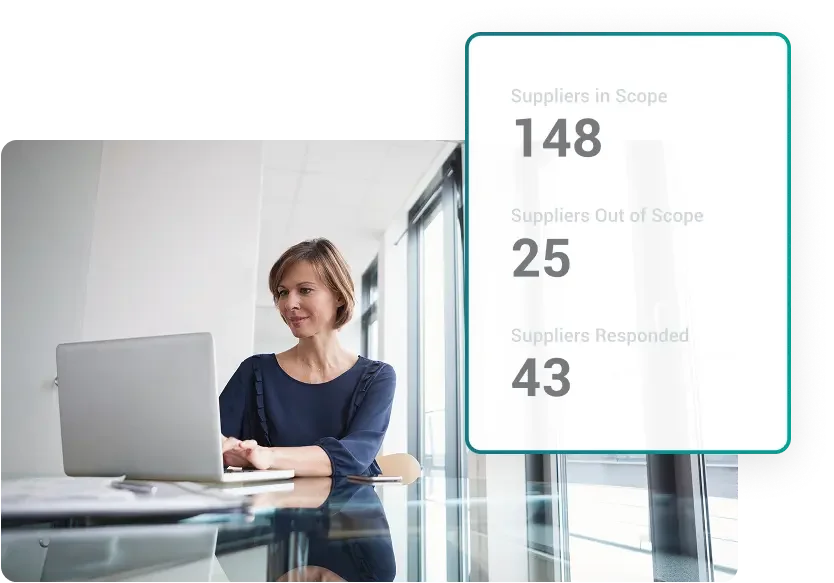

Assent’s RoHS solution helps you proactively address upcoming RoHS exemption expirations and track which exemptions are used in your supply chain. We automate the collection of product compliance and parts information from your suppliers, giving you the transparency needed to quickly identify your risk exposure to proposed RoHS regulatory changes.

In addition, our team of regulatory experts carefully monitors the regulatory landscape and the European Commission’s publications to make sure you’re in the know about potential updates. We even have membership in some industry associations so we can help industry respond and shape the future of product compliance requirements.

To learn more about RoHS compliance, and how Assent partners with companies like yours to reduce their supply chain risk, check out our online RoHS resources.