The recent wave of regulatory delays across the manufacturing sector shouldn’t be mistaken for a slowdown. In reality, this pause marks a period of recalibration that manufacturers can use to their strategic advantage. Businesses should be using the extra time to demonstrate preparedness and reliability to their customers and stakeholders, proactively managing their supply chain compliance data to ensure it doesn’t delay deals, derail audits, or create uncertainty.

Governments across North America and the EU are modernizing how data is collected, verified, and shared. Postponements to the EU Deforestation Regulation (EUDR), EU Batteries Regulation (EUBR), and proposed changes in the Omnibus Simplification Package illustrate a broader pattern: Regulations aren’t being scaled back; they’re being refined to handle the scale and complexity of global supply chain data.

This is the calm before the compliance storm. As reporting frameworks become more interconnected and digitalized, it’s urgent for manufacturers to act now. It’s time to strengthen data systems, align teams, and engage suppliers before the new wave of enforcement deadlines arrive. Those manufacturers who turn delays into a head start on supply chain due diligence can turn the current regulatory landscape into a competitive advantage.

Delays Don’t Mean Fewer Data Requirements

When a regulation is delayed, it’s easy to assume that requirements have softened. In reality, regulators expect the volume and complexity of supply chain data won’t shrink or slow down. Most of the recent reporting postponements are happening because authorities are fine-tuning digital systems and definitions, and not because they’ve reduced the scope of requirements for businesses.

Use this time to gather cleaner, more complete data and avoid the last-minute scramble from the unavoidable influx of requests for data as the new deadline approaches.Supplier engagement, documentation of materials and origins, and validation processes all take months to refine. Companies that start early build stronger supplier relationships, and have time to validate data and educate suppliers. Those who wait often find themselves competing for supplier attention and racing to fix gaps under pressure.

Get expert advice on improving your compliance program so you can stay productive and profitable, even as regulations evolve. Download our guide Closing the Risk Gap: From Supply Chain Chaos to Strategic Advantage today.

The Value of Proactive Compliance, Even With Deadline Extensions

A reactive compliance strategy waits for enforcement deadlines. A proactive one anticipates them and gains efficiency, customer confidence, and competitive advantage along the way. It pays for itself through reduced rework, fewer disruptions, and greater supplier trust.

Manufacturers who act early will:

- Spread compliance tasks and costs over time, rather than absorbing them in one inefficient sprint

- Reduce risks of financial and reputational damage that come with missed deadlines or incomplete reporting

- Engage and educate suppliers to improve data quality, reducing time spent on follow up emails and fixing bad data

For mid-tier suppliers, proactive compliance can be a game-changer. Large customers increasingly expect real-time access to compliance and sustainability data, and they prioritize suppliers who can deliver it quickly. If you can provide validated declarations well ahead of the extended deadlines, you’re not just compliant, you’re valuable. You become the dependable partner who makes it easier for customers to meet their own obligations.

Regulators Are Streamlining — to Collect More Data, Not Less

Governments are not pulling back on their expectations for product sustainability. Instead, they’re building the infrastructure to enforce due diligence requirements more effectively. Across jurisdictions, delays reflect a surge of investment in data systems, verification tools, and digital reporting frameworks designed to make compliance more precise and interconnected than ever before.

- The EU Deforestation Regulation (EUDR) is facing a proposed one-year delay, not because expectations are easing, but because the information system meant to handle operator data isn’t yet ready. That’s partially because EUDR deals with complex geolocation data from your supply chain. But there’s already pushback from Parliament on this delay, showing you can’t assume deadlines will move just because there’s a published proposal.

- Minnesota’s PFAS reporting requirement has been pushed back six months, giving manufacturers a short extension to give the state’s governing body time to finalize its submission systems.

- The EU Batteries Regulation (EUBR) has been delayed by two years to allow time to align EUBR with the Corporate Sustainability Due Diligence Directive (CS3D) to ensure that the same standards of environmental and human-rights due diligence apply across industries. In other words, the goal is harmonization to enable more consistent, comparable, and enforceable data across markets.

Taken together, these developments point to a future where compliance is data-centric. Regulators are investing in software, analytics, and system integrations to make supply chain transparency measurable and verifiable at scale. The logical parallel for manufacturers is clear: if regulators are building systems to collect more data, manufacturers must build systems to manage, organize, and deliver it.

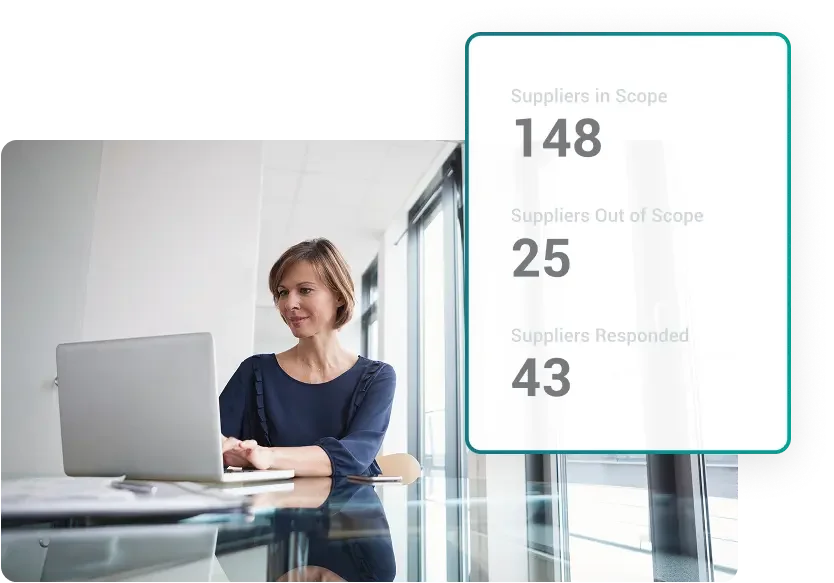

That means investing in supply chain sustainability data management software that can centralize supplier information, automate outreach, and maintain audit-ready records.

Get Moving Before the Storm Hits

The global regulatory landscape is shifting faster than ever. Laws are evolving, expectations are converging, and data demands are expanding across every tier of the supply chain. Delays may buy time, but they don’t change direction.

It’s time to get ready. Strengthen supplier networks, organize data systems, and refine your sustainability reporting. Companies investing in supply chain sustainability software and product compliance software now are future-proofing their operations. Because when the deadlines arrive, manufacturers that moved early will already be compliant and positioned to grow while others are still scrambling to catch up.

In short: When regulations stall, get moving. That’s how you turn regulatory delays and downtime into a competitive advantage. Take the first step by speaking with an Assent regulatory specialist.

FAQ: Managing Regulatory Delays & Changes

Learn how to turn regulatory delays and other changes into a competitive advantage with answers from our experts.